OUR LAB

QC Process

BOGCL has a very well equipped laboratory with cutting

edge technology where skilled expertise assure high

quality bituminous products. A large number of different

tests are performed on bituminous materials by skilled expertise, chemists for the purpose of checking compliance with

the specifications (ASTM, AASHTO, BOS: EN, GB/JTG

F40, IS etc.) that are being used. For quality control and quality assurance BOGCL offers

various testing facilities-

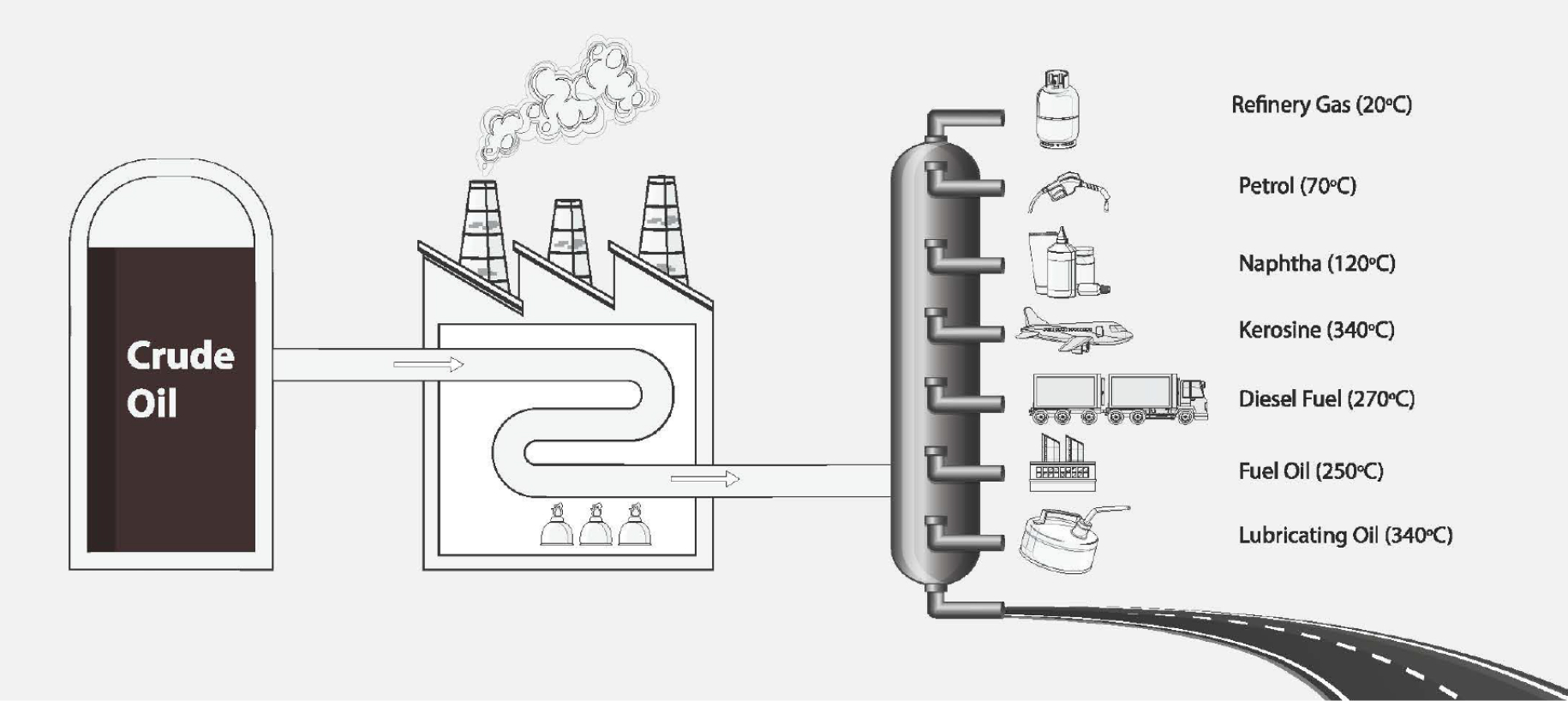

CRUDE OIL DISTILLATION

- ATMOSPHERIC DISTILLATION- ASTM D86

- VACUUM DISTILLATION- ASTM D1160

LABORATORY TESTS OF BITUMINOUS MATERIALS

- Penetration- ASTM 05

- Softening Point (Ring & Ball)- ASTM 036

- Specific Gravity- ASTM 070

- Kinematic Viscosity- ASTM D 217

- Absolute Viscosity- ASTM D 2171

- Ductility- ASTM 0113

- Solubility in trichloroethylene- ASTM D4042t

- Water Content- ASTM 095

- Spot test AASHTO T102

- Solubility in trichloroethylene- ASTM D4042t

- Water Content- ASTM 095

- Flash point (Cleveland Open Cup)-ASTM D 92

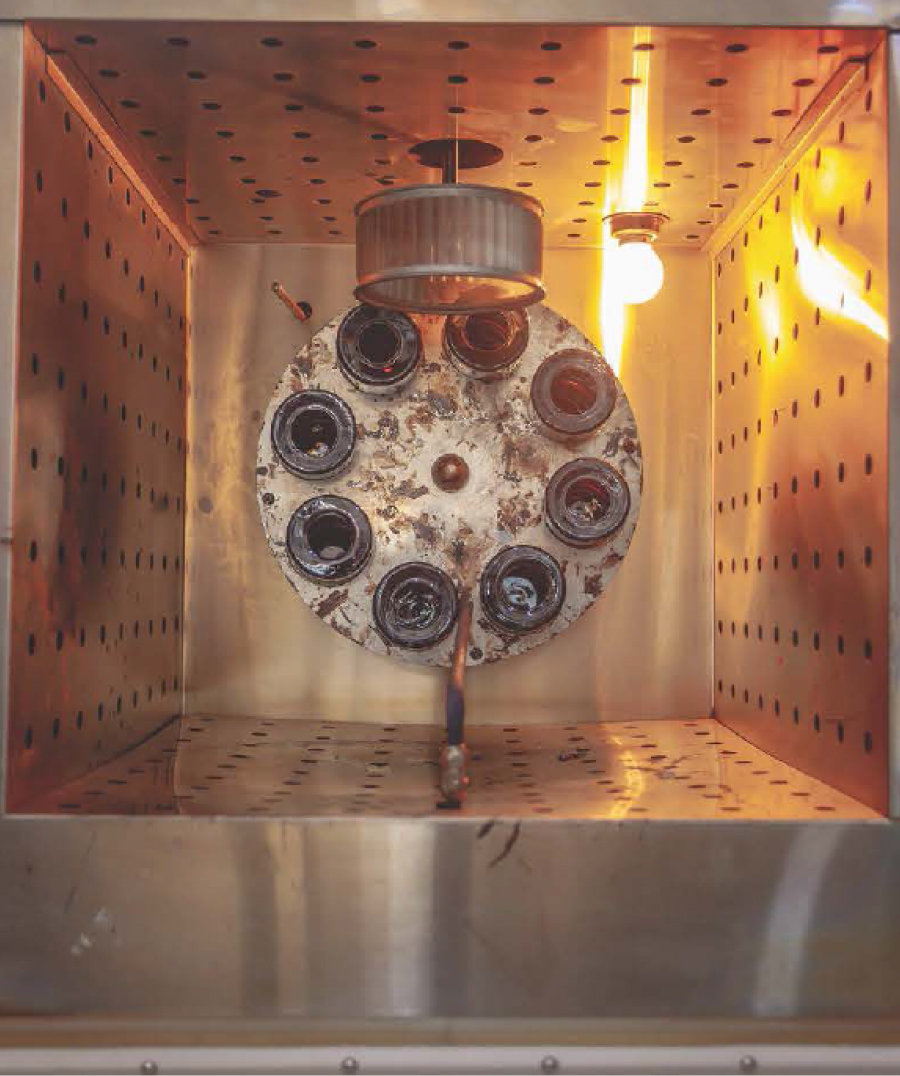

AGING TEST OF BITUMEN:

IMPORTANCE OF AGING TEST:

The Rolling Thin-Film Oven (RTFO)-ASTM D2872 procedure provides simulated short term aged bitumen for physical property testing. Bitumen is exposed to elevated temperatures to simulate manufacturing and placement aging. Seeing as the constituent bitumen in Hot Mix Asphalt undergoes significant aging during the manufacturing and placement processes, a method to simulate the aging is important in investigating and predicting early age HMA pavement behavior and distresses.

The Rolling Thin-Film Oven (RTFO)-ASTM D2872 procedure provides simulated short term aged bitumen for physical property testing. Bitumen is exposed to elevated temperatures to simulate manufacturing and placement aging. Seeing as the constituent bitumen in Hot Mix Asphalt undergoes significant aging during the manufacturing and placement processes, a method to simulate the aging is important in investigating and predicting early age HMA pavement behavior and distresses.

BY RTFOT TEST

- Bashundhara cutback bitumen has some significant properties:

- Any tests on residue can be measured which shows the bitumen performance during construction and predicts its lifetime.

- Loss of volatiles or mass change can be measured.

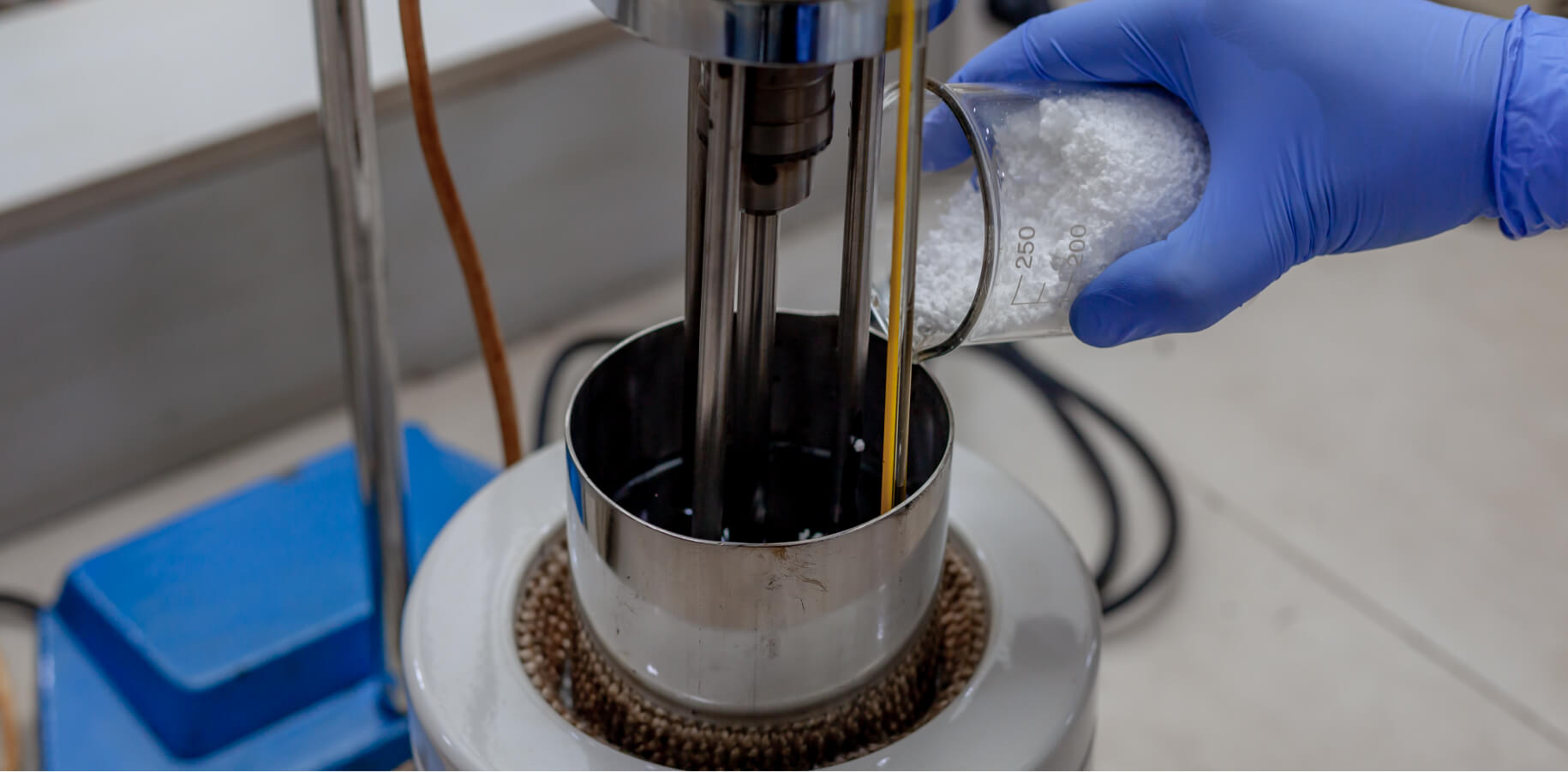

IMPORTANCE OF VISCOSITY GRADE

Viscosity grade bitumen has been adopted in 1970 where Penetration grade was stablished 1903. Viscosity grade is more performance based test as its main test is viscosity at 60 oC (Near maximum surface temperature of the pavement) and 135 oC(Near mixing and laydown temperature of asphalt mix) rather penetration test is more likely consistent test. BOGCL offers two advanced viscosity test facilities-

- Absolute viscosity at 60 oC (Vacuum Capillary Viscometer)-ASTM D2171

- Kinematic Viscosity at 135 oC (Brookfield Viscometer)- ASTM D4402

POLYMER MODIFIED BITUMEN

FORMULATION AND ANALYSIS FACILITIES: BOGCL laboratory has the very advanced facilities of PMB formulation and analysis.

- High shear mixing for ............ SBS

- Low shear mixing for ............. of PMS

- Fluorescence Microscopy Image for PMS

- Elastic Recovery (PMB)-ASTM D 6084/ EN-13398

- Storage Stability (PMB)- ASTM D 5892

- Dynamic Viscosity- ASTM 04402

- Low Temperature ductility JTG E20 - T0605

- Force ductility- EN-13589

- Aging Test-RTFO- ASTM 02872

- Dynamic Viscosity- ASTM 04402

BOGCL 1s also introducmg performance grade Bitumen - AASHTO M320 and AASHTO M332 very soon. And there will be facilities of conduction tests for PG Binder.

- DSR- Dynamic shear Rheometer tor viscous and elastic behavior

- BBR- Bending Beam Rheometer- for Low temperature stiffnes

- DTI-Direct tension tester-for Low temperature stiffness and relaxation

- PAV-Pressure Aging Vessel -for Ion term aging measurement.

EMULSIFIED BITUMEN

FORMULATION AND TESTING FACILITIES: BOGCL laboratory has very advanced facilities for formulation

of Emulsified bitumen -both Cationic and Anionic of rapid,

medium and slow setting.

- Any test on Residue for bitumen Emulsion (Evaporated Residue)- JTG E20-T0651

- Angler Viscosity for bitumen Emulsion- JTG E20-T062

- Emulsified Bitumen and Mineral Aggregate Mixing Test- JTG E20-T0659

- Adhesive Test of Emulsified Bitumen and Coarse Aggregate- JTG E20-T0654

- Break Speed Test of Emulsified Bitumen- JTG E20-T0658

- Particle Ionic Charge Test in Emulsified BitumenJTG E20-T0653

- Oversize Residual Content Test in Emulsified BitumenJTG E20-T0652

CUTBACK BITUMEN

FORMULATION AND TESTING FACILITIES: BOGCL laboratory has very advanced facllrties for formulation

of cutback brtumen of rapid curing type, medium curing type

and slow curing type.

- Distillation of Cutback Bitumen at various temperature -AASHTO T78, ASTM 0402

- Any tests on residue content by distillation -ASTM/AASHTO

- Kinematic Viscosity at 60 oC by Reverse flow viscometer -ASTM D 445

RESEARCH AND DEVELOPMENT

FOR BASHUNDHARA OIL AND GAS COMPANY LIMITED:

Technical Support represents complex scientific and technical solution based on professional expertise of Civil Engineers who analyses the field of modern pavement engineering. R&D for bituminous materials under BOGCL implements the full cycle of field and laboratory tests of bitumen, bitumen derivatives, and asphalt-concrete mixtures. Technical capabrlit ies of the company enable simulation of actual traffic loads, traffic intensity and patterns, as well as climatic conditions rn different regions. R&D experts develop indrvidual recipes of bituminous materials and asphalt-concrete for each particular case of operational conditions and subject to analysis of local inert matenals: crushed rock and sand. For Bitumen application and BGCL R& D offers very well equipped facilities:

Technical Support represents complex scientific and technical solution based on professional expertise of Civil Engineers who analyses the field of modern pavement engineering. R&D for bituminous materials under BOGCL implements the full cycle of field and laboratory tests of bitumen, bitumen derivatives, and asphalt-concrete mixtures. Technical capabrlit ies of the company enable simulation of actual traffic loads, traffic intensity and patterns, as well as climatic conditions rn different regions. R&D experts develop indrvidual recipes of bituminous materials and asphalt-concrete for each particular case of operational conditions and subject to analysis of local inert matenals: crushed rock and sand. For Bitumen application and BGCL R& D offers very well equipped facilities:

- Asphalt Concrete Mix Design-Marshall Method-ASTM/AASHTO

- Job Mix Formula-ASTM/AASHTO

- Bulk Specific Gravity of HMA- AASHTO T166

- Theoretical Maximum Specific Gravity·AASHTO T209

- Indirect Tensile test or resistance to moisture damage -AASTOT 283

BOGCL -R&D; Technical Support also provides support on-

- Marshal Flow & Stability Test-AASHTO T 245

- Wheel tracking test- JTG E20-T0719

- Bitumen Content test by ignition- ASTM 06307

- Asphalt Slab Roller Compactor

- Value added bitumen application troubleshooting

- Product specification

- Quality

- Test methods

- Equipment

- Procedures and bitumen technical information on safety, storage, and handling